Internal vs External Snap Ring – Difference Between Internal and External Snap Ring

You probably need some snap rings for your mechanic purposes. Still, you don’t know what type is good for you between internal and external snap rings. This content will give you details about the internal and external snap rings with a broad overview where you will get their differences and advantages, and disadvantages.

So, Internal vs. External Snap Ring— here we’ll go.

What is the snap ring?

Snap rings are strong, thin, and C-shaped metallic rings used to work as retaining fasteners for assembly parts on shafts and inside circular bores and grooves. This tool is different from nuts and bolts, and it contains high tensile strength to snap into the radial groove and stay in place.

You will find different types of snap rings on the market, such as tapered section, constant section, spiral lock snap ring, and more. They mainly belong to two types: internal snap rings and external snap rings.

Internal snap rings are types of retaining rings usually installed inside the bores or housing to sustain and protect assemblies and components from coming out. On the other hand, external snap rings are ring types used to wrap around a shaft to keep shaft assemblies. You can use it in many applications like bearings and gear assembly.

Differences between internal vs. external snap ring

In the above, you got the definition of the snap ring and its main two types. Now, you will get clear ideas of the internal and external snap rings and their differences.

When identifying internal and external snap rings, you will get various differences between them as they are designed for use for distinct purposes. Here I am mentioning some differences between them.

- The internal snap ring is usually installed inside the bores. In contrast, the external snap ring is installed outside on a shaft.

- The internal snap ring needs to be compressed when installing or removing. In contrast, the external snap ring has to be expanded for the same activities.

- The internal snap ring basically makes contact with its external circumstance, while the external snap ring makes contact with its internal circumstance.

These are some basic differences between internal and external snap rings. You will get every detail in the following overview part of the content. So, let’s get it.

Overview of the internal snap ring

Internal snap rings are designed to be set in the bores and are made in metric and imperial sizes. These types of rings provide high performance and durability, and they also offer resistance to corrosion.

This ring is usually made from spring steel 70C6 or 75C6 grade and contains an outer diameter of 8mm to 500mm and a thickness of 0.4mm to 6mm. You will get them available in standard and customized sizes.

Who is it for

When reading the content up to this line, it may be clear who use internal snap rings. If it’s not, don’t worry; I am clearing it up.

Internal snap rings are made for any mechanical person who works in a car garage, machine, turbine, or manufacturing company. This ring also has heavy usage in ship repair, harbor, railway, and construction purposes.

What is the purpose of the internal snap ring?

The internal snap ring is designed to be used in the bores or housing to prevent assemblies or components from coming out. It ensures quality services with long durability.

You can use them for multiple purposes like heavy machine manufacturing, mining, railways, construction, turbine manufacturing, the energy sector, port, harbor, and ship repairing.

The advantages and disadvantages of internal snap ring

Apart from the above facilities and services, internal snap rings contain more advantages and disadvantages. Here you can find them.

Advantages

- Considerably Lightweight

- It significantly reduces the production cost

- It doesn’t need any special training for assembly.

- It’s easier to install and can be assembled faster.

- It takes less amount of raw material for any given size.

- It’s compact in design and cheaper than other fastening methods.

- It lessens and avoids complex machining such as undercuts and threads.

Disadvantages

- It’s designed for only internal use.

- It contains less housing/shaft preparation.

- There will be a small play in the axial direction.

Overview of the external snap ring

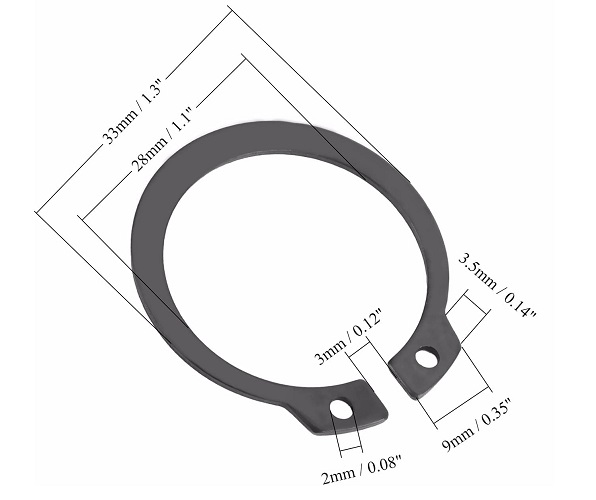

The external snap ring is designed to be installed in the grooves and shafts. It’s made in metric and imperial sizes that can tightly fit around a shaft or groove.

It contains an outer diameter range of 6mm to 500mm and a thickness of 0.4mm to 6mm. You can use this for numerous machine, energetic, ship-repairing, motors, pistons, and turbine activities.

Who is it for

Generally, any person can use external snap rings for various mechanic activities like car and ship repairing, industrial and energetic manufacturing, and many other applications.

What is the purpose of an external snap ring?

External snap rings are designed to use in the shafts or grooves, and they are used to replace nuts, threaded sleeves, cotter pins, rivets, set collars, machine shoulders, and other expensive fastening devices.

Apart from this, you can use external snap rings such as bearings on axles and gear assembly inside the transmission.

The advantages and disadvantages of external snap ring

Advantages

- It’s cheaper than other fastening methods.

- It takes lower production and buying costs.

- It’s easier to install and comparatively lightweight.

- It has a compact design and takes less raw material to produce.

- It needs no special training for assembly and can be assembled very fast.

Disadvantages

- It’s designed for only external usage.

- The weight and size of the finished design are significantly reduced.

Internal vs. External snap ring – Head-to-head comparison

You already know the details of internal and external snap rings. And here, you will learn some head-to-head comparisons between them.

Sizes/Diameter:

In diameter and size, Internal and external snap rings usually contain .375 in. to 10 in. diameters, 13 mm to 300 mm. Also, they include different ranges of diameters from 0.500 to 60 inches on standard, round rings; diameters from 2.5 to 11.5 inches on elliptical rings;

diameters from 3 to 7.5 inches on wave rings.

Designed:

Internal snap rings are designed to use in the bores and housing, whereas external snap rings are designed to use in the shafts or grooves.

Material & Finish Type:

There is no difference in material process as both rings are made from different steel like beryllium copper, carbon spring steel, and stainless steel.

Shaped/Style:

Both snap rings contain different types of shapes and styles, such as C shapes, E shapes, CA shaps, and more.

Thickness:

According to different types and sizes, snap rings contain various thickness capacities from .015 to .050.

Measurement System:

To measure internal snap ring—

- Slide open the main jaws

- Tighten the screw clamp

- Place the snap ring between the jaws

- Read the main scale and the vernier scale

- Close the calipers on the fastener until it is secure

To measure external snap ring—

- Put the jaws inside the external circlip.

- Place the external circlip on a flat surface

- Close the smaller jaws of the vernier caliper

- Read the vernier caliper and record the measurements.

- Tighten the screw clamp to keep the measurement from changing.

Everything You Wanted to Know About Snap Ring Pliers

Important Questions of Snap Ring

What are snap ring pliers used for?

Snap ring pliers install and remove snap rings of the shafts, grooves, and bores. Different snap ring pliers are designed for the particular snap ring installation.

What are the best snap ring pliers?

Several brands, such as Milwaukee, Makita, and many others, manufacture the best snap ring plier sets.

What can I use instead of snap ring pliers?

You can use needle nose pliers instead of snap ring pliers because they are similar.

What size snap ring pliers do I need?

It depends on what kinds of snip rings you use because snap ring pliers vary according to the snap ring types, sizes, and categories.

Where to buy snap ring pliers?

You will get snap ring pliers at your nearby tools shops. Also, you can buy snap ring pliers at online stores like Vermont Tool Company.

Final Thoughts

Snap rings are such rings used to work as retaining fasteners for assembly parts on shafts and inside circular bores and grooves. In this article, you got a broad overview of internal vs. external snap rings, their overall differences, and their advantages and disadvantages during use.

Now, you can easily decide what type of snap rings you need. So, go forth and buy your tools.